Recently viewed

Frequently Asked Questions about ATEX / Explosion Proof Lighting

ATEX refers to the EU Directive 2014/34/EU, which covers equipment used in potentially explosive atmospheres. ATEX-certified lighting is specially designed to prevent sparks, arcs, or excessive heat that could ignite flammable gases, vapours, or dust.

ATEX lighting is required in any workplace where explosive atmospheres may occur. This includes chemical plants, oil & gas facilities, fuel storage, paint shops, flour mills, and wastewater treatment sites. Areas are classified into Zones (0, 1, 2 for gas; 20, 21, 22 for dust), and the correct ATEX light must be chosen for the zone.

Zone 1: An area where explosive atmospheres are likely to occur in normal operation. Requires high-specification ATEX luminaires. Zone 2: An area where explosive atmospheres are unlikely, or only occur infrequently. Lower-rated ATEX fittings may be suitable. Always match the product certification to the zone classification.

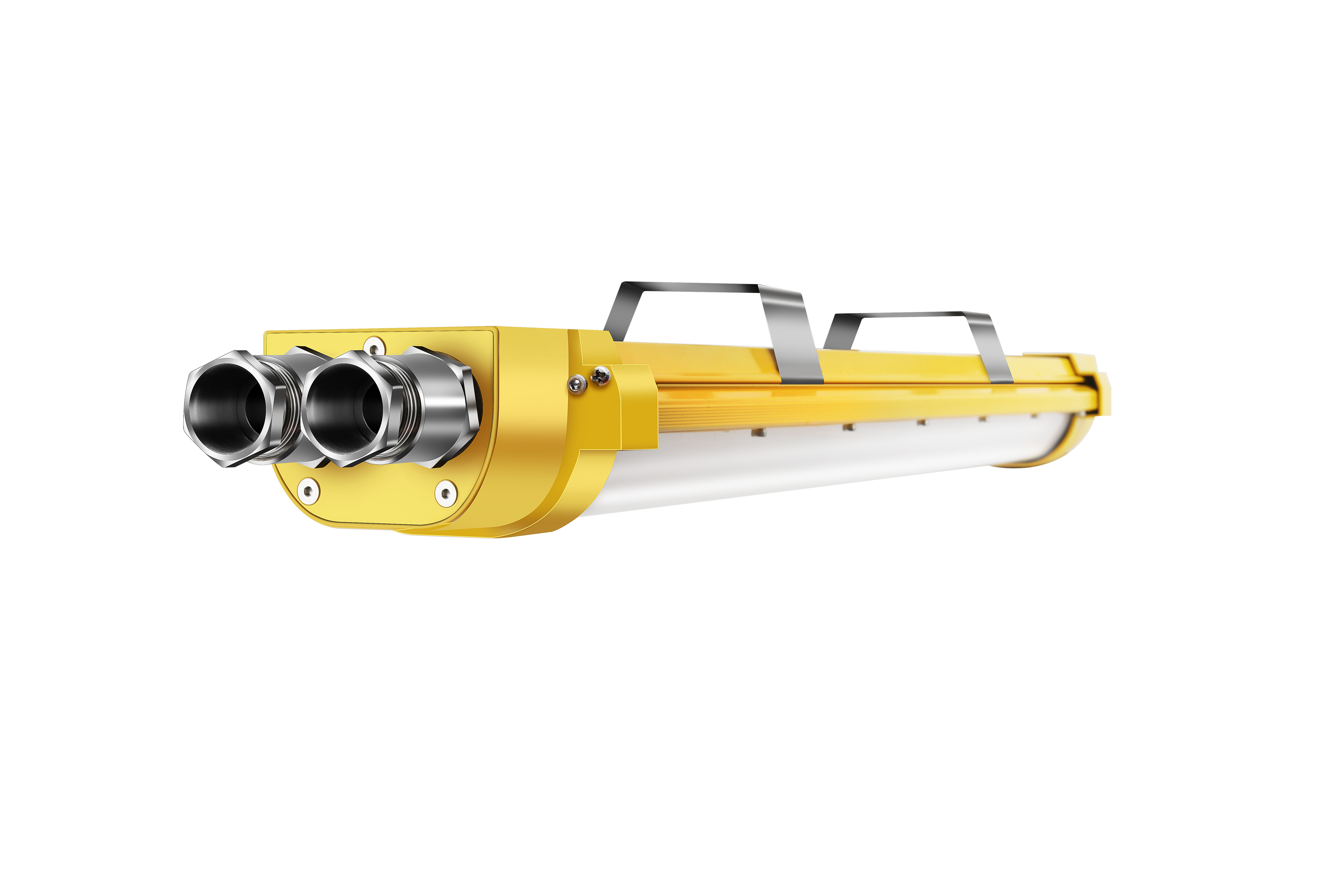

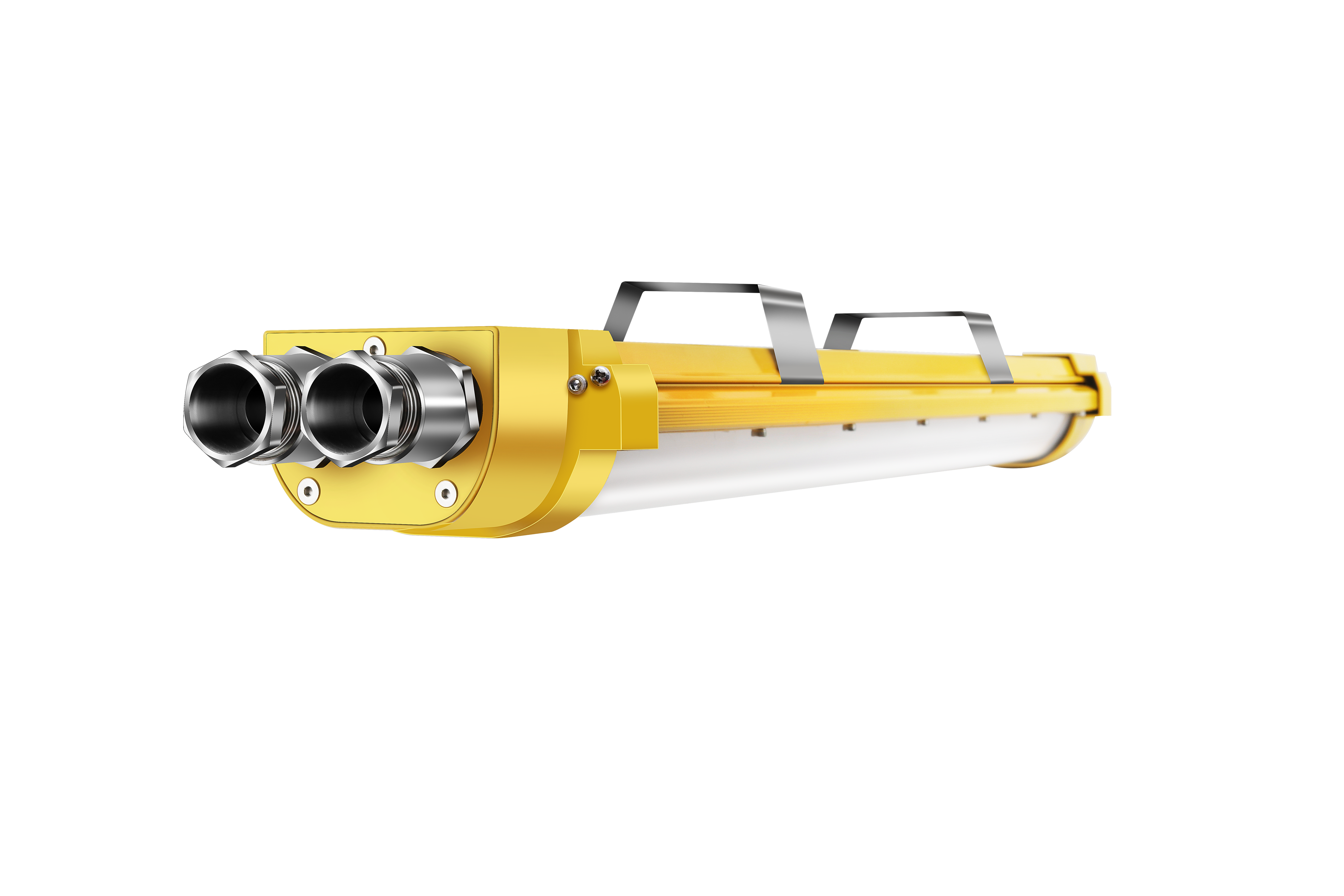

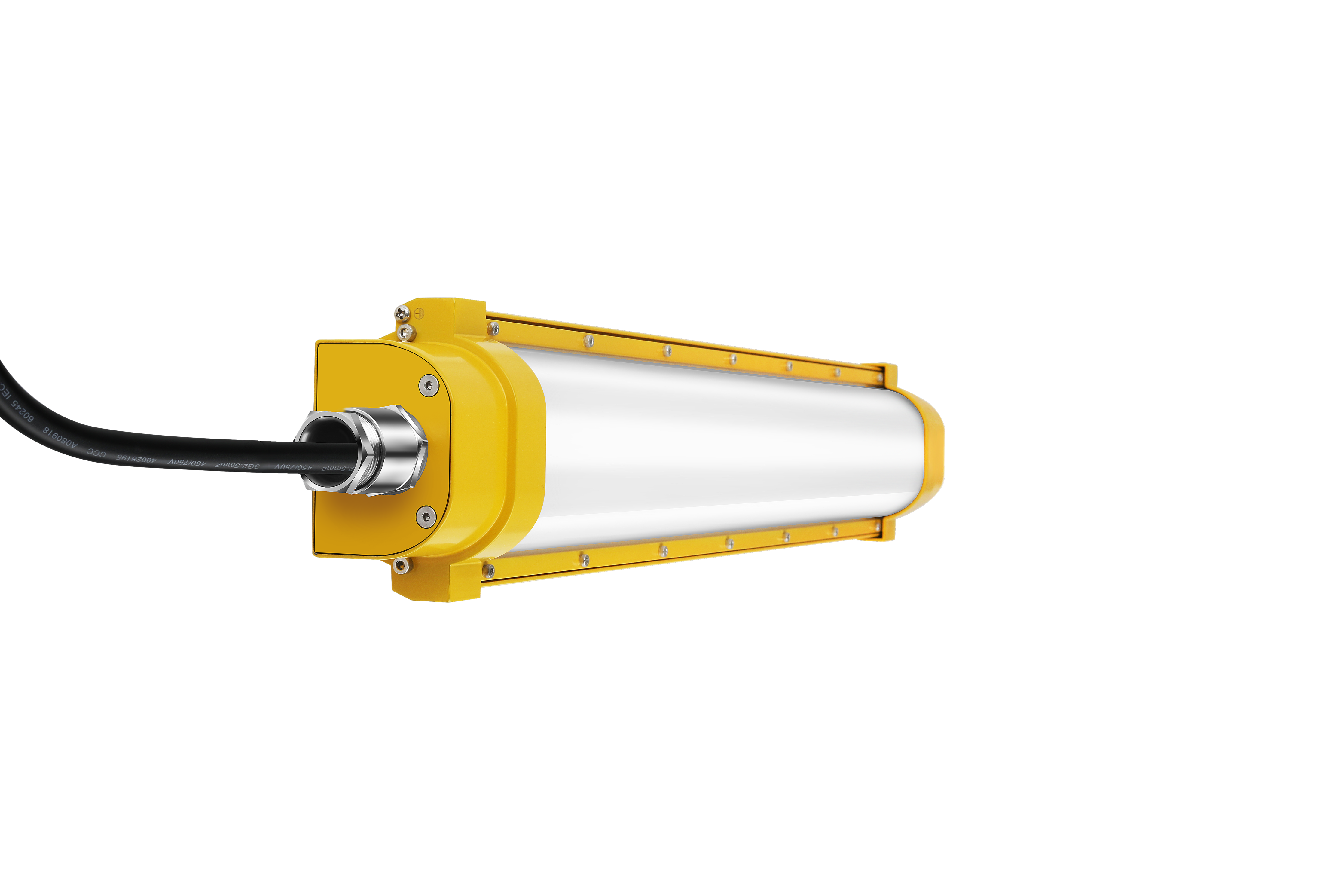

Yes. Modern ATEX LED lights combine energy efficiency with explosion protection. Compared to traditional fluorescent or HID, LED ATEX fittings offer longer lifespans, lower running costs, and reduced maintenance in hazardous environments.

Every ATEX light should carry an Ex marking on its label and certification paperwork. This marking shows the equipment group, category, protection method, gas/dust classification, and temperature rating. Always request certification documents to confirm compliance.