LED Wattage Guide: Equivalent Replacements for Traditional Bulbs & Lamps

Upgrading to LED and not sure what wattage you need? Use this guide to match LED equivalents to incandescent, halogen, CFL, fluorescent, SON and metal halide lamps — with trade-focused tips and real savings examples.

Why wattage equivalence matters

Traditional lighting measured brightness by watts — more watts generally meant more light. With LED, brightness is measured in lumens, and LEDs deliver far more lumens per watt (they’re much more efficient). That’s why LED wattages are dramatically lower for the same light output.

- A 60W incandescent produces ~800 lumens.

- An 8–10W LED can produce the same ~800 lumens.

Understanding equivalence prevents over/under-lighting and ensures you capture the full energy-cost savings from your upgrade.

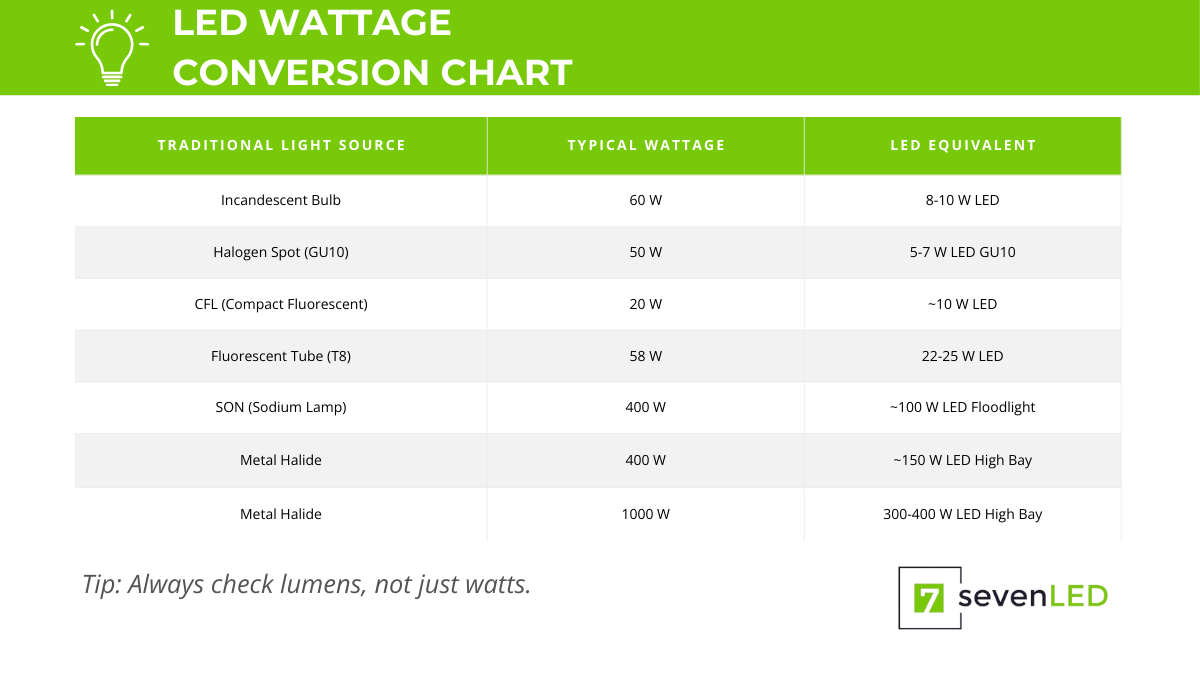

LED vs traditional wattage conversion chart

Use this quick reference when specifying replacements. Always confirm the lumen output and application requirements.

| Traditional light source | Typical wattage | LED equivalent | Example application |

|---|---|---|---|

| Incandescent bulb | 60W | 8–10W LED | Small offices, domestic fittings |

| Halogen spot (GU10) | 50W | 5–7W LED GU10 | Retail spotlights, displays |

| CFL (compact fluorescent) | 20W | ~10W LED | Task lighting, lamps |

| Fluorescent tube (T8) | 58W | 22–25W LED batten | Offices, corridors, schools |

| SON (high-pressure sodium) | 250W | ~100W LED flood | Car parks, security lighting |

| Metal halide | 400W | ~150W LED high bay | Warehouses, factories |

| Metal halide | 1000W | 300–400W LED high bay | Large distribution centres |

Trade tip: treat the table as a starting point. Specify by lumens for accuracy, then confirm beam angle, mounting height and spacing.

LED savings in real numbers

Lower wattage translates directly into energy cost reduction and easier maintenance.

Example:

- 400W metal halide high bay running 12 h/day, 5 days/week ≈ 3,120 h/year → ~1,248 kWh/year.

- At £0.30/kWh = ~£375 annual running cost per fitting.

- Replace with 150W LED high bay → ~468 kWh/year = ~£141/year.

Saving: ~£234 per light, per year. Scale that across 50–100 fittings and annual savings can reach tens of thousands of pounds.

Choosing the right LED replacement

- Lumens (brightness): match to task and mounting height.

- Colour temperature (K): 4000–5000K for warehouses/offices; 3000K for hospitality/reception.

- Beam angle: wide beams for general areas; narrow for racking/task zones.

- CRI: higher CRI improves colour accuracy (retail, print, inspection).

LED equivalence by application

Warehouses & factories

Replace 400–1000W metal halide with 150–400W LED high bays for instant-on, high efficacy and long life.

Offices & schools

Replace fluorescent panels/tubes with LED panels or battens for improved efficiency and uniformity.

Outdoor & security

Replace 250W SON with around 100W LED floods for better colour rendering and reduced light pollution.

FAQs: common questions on LED wattages

What LED replaces a 60W bulb?

Typically an 8–10W LED producing ~800 lumens. Always check lumens on the pack.

Why does LED use fewer watts?

LEDs convert far more electrical energy into visible light (higher efficacy) and waste less as heat, so they need fewer watts for the same lumens.

How do I calculate LED equivalence?

Start with the lumen output of the old lamp. Specify an LED that delivers similar or improved lumens for the task. Don’t match watt-for-watt.

Can I just swap an old fitting with an LED one?

Many lamps are retrofit, but for commercial upgrades (e.g. warehouse high bays), verify electrical compatibility and photometric performance. Our team can advise.

Ready to specify the correct LED?

Get a fast, trade-friendly quotation with product recommendations tailored to your site.

Request a free lighting quote | Shop LED High Bays | Shop LED Panels